Well operations with umbilical

Description

At the present time, most of the oil in Russia is produced from wells with low and average flow rate; these wells are operated 15-30 years already. Comparing wells with high flow rate, operation of wells with low flow rate has the following features:

- Oil produced has

a high content of water and high concentration of salts; This leads to the

laying of salts on submersible equipment and inside of the production tube;

- Installations of

electric centrifugal pump producing 15 to 30 m3/day have a low

efficiency that results increased heat emission and laying salts on them;

- Rate of rise of the

fluid is low, and laying of paraffin and hydrates inside production tube is

more intensive.

All above-mentioned leads to often failure of an electric centrifugal pump and to a necessary rise of the installation. As a result, a significant part of costs of well operation spent on overhaul of wells, and saving these costs and time for the overhaul operations allows to increase profitability of use of wells with low flow rate.

One of the ways to save these costs is use of an umbilical.

Specifications

Fig.1. Laying of salts on parts of electric centrifugal pump

Advantages of the umbilical over usual column of the production tube:

- time of operations

is decreased sharply because winding of the production tube is excluded. Speed of

lowering and rising will be 1000 m/hour;

- safety of works is increased because performing operations personnel is not

nearby but only controlling lowering process;

- as the umbilical produced by single length, not hermetic area in connection points of two pipes are excluded;

- reduced possibility to damage power conductors because they protected by an armouring sheath which has excellent damping and protective properties.

Hydraulic characteristics of the steel polymer pipes are superior to the production tube. This allows using pipes with the small section and same values of losing the pressure by friction on the walls (Fig.3).

The process of laying asphalt-resin-paraffin substances inside of the pipe is significantly less intensive.

Since 2008, OOO “Pskovgeokabel” along with OAO “NOVOMET-Perm” develop the system umbilical-electric centrifugal pump for the umbilical production of oil.

In March 2009, the company “OKBBN “KONNAS” on the well No4 performed testing of the umbilical TG 30/62-250 (3x16+4x0,75+GK3) with suspended installation of the electric centrifugal pump 5.1-200-350. These tests were successful and showed that the designed umbilical and terminal elements provide functioning of the installation of the electric centrifugal pump.

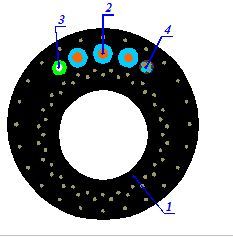

Design of the umbilical ÒG 30/62-250 (3x16+4x0,75+ÃÊ3) is shown on Fig.2.

Fig 2. Design of umbilical TG 30/62-250 (3x16+4x0,75+ÃÊ 3).

1 – steel polymer pipe;

2 – electrical cable;

3 – capillary tube

4 – signal conductors

The umbilical is produced on the base of a steel polymer pipe (Position 1). Three power conductors with section 8 to 16 mm2 are included to the umbilical for the power supply of the electric centrifugal pump. The capillary tubes (Position 3) are designed for the supply of inhibitors to an inlet of the pump. The control conductors (Position 4) are designed for the transfer of submersible telemetry from the installation of the electric centrifugal pump, and geophysical block lowered under the pump.

The umbilical is produced by the single length and winded on a reel of lowering-rising assembly depicted on Fig.3.

This assembly

allows performing bystages:

- mounting

of installation of electric centrifugal pump to the well;

- connection of the installation with the umbilical;

- lowering of the umbilical to the required depth of suspension;

- installation of the fountain equipment.

Fig. 3 Assembly for lowering and rising of electric centrifugal pump on umbilical

The terminal elements allow fast and reliable connection of the umbilical with any type of installation of electric centrifugal pump and a fountain armature used by oil productive companies.