Well electric heater

Description

ÎÎÎ “Pskovgeokabel” offers to supply additional equipment to prevent asphalt-resin-paraffin deposits in oil and gas wells used with heating cables KGn. Well electric end heater EKS designed for melting of paraffin hydrates plugs and to facilitate lowering of the heating cable to a well when solid deposits available.

Lowering of usual heating cable requires preliminary heat working of a well to free the production tube from the paraffin-hydrates plugs. Use of the end heater allows excluding this expensive procedure. When lowering the heating cable, the heater, disposed at the end of cable, is heated to temperature of melting the paraffin plugs and forms a channel for the cable.

Specifications

Technical characteristics of well electric end heater EKS-5:

|

Property |

EKS-5 |

|

Nominal power, kW |

5 |

|

Maximal outer diameter, mm |

45 |

|

Length of heater, mm |

1500 |

|

Pressure, ÌÐà |

20 |

|

Supplied voltage, V |

380 |

|

Maximal temperature, °Ñ |

250 |

The heater produced in a conventional version and with a stainless steel housing. For comfortable transportation and installation, the electric heater connects to the cable with a sealed load carrying connector.

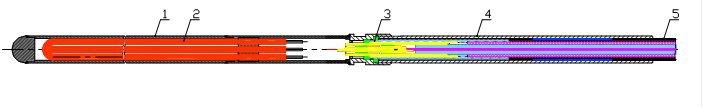

Design of heater

A releasable connection used for comfortable transportation of the cable and end heater to a place of lowering. A mating connector is installed on the cable termination (4). The cable termination is set on the lower end of the heating cable (5), sealed and pressurized to an operational pressure at the factory. The function of the cable termination is load transfer from the heater housing to armour of the cable when pushing or rising the cable and providing of sealing.

Technology of operation:

After delivery of the cable and end heater to a place of lowering, the end heater is mounted to the adapter at the lower end of the descended cable KGn, with the hermetic releasable connection. Inner conductors of the cable KGn designed for power supply of the end heater over a brush collector at a lowering rising machine (logging winch), connected to the heating control cabinet UPS where an additional control and protecting equipment is installed.

Lowering of the cable with electric heater performed through a lubricator. After lowering, central conductors are disconnected from the brush collector, and the end heater is off. The cable fixed by two locks (main and reserve). The wellhead is sealed and shutters of flowline are closed. Further, the heating cable is connected to the control station by a standard scheme with temperature control by resistance of a heating loop. Thawing of the well is performed during around 8 hours, and then the shutters open. The specially designed heating control station produced by OOO “Pskovgeokabel” allows simultaneous performance of the end heater and heating cable that significantly increases effectiveness of the heating system.

Heating cable, with installed cable terminal for connecting the end heater, can be used without EKS, and then a hermetic cap is set instead of the heater.

EKS can be used without heating cable to puncture the plugs of asphalt-resin-paraffin. In this case, a load carrying cable of increased rigidity with additional loads is used for lowering of the heater, and the winch is equipped with a separated control cabinet for managing of the heating.