Capillary high pressure pipelines

Description

Now, oil production has complexities connected with increase of corrosion activity of output products, formation of deposits of not organic salts and asphalt-resin-paraffin substances, formation of stable emulsions. Quantity of complicated oil wells is growing constantly by all production companies. The company ÎÎÎ «Pskovgeokabel» is developed capillary polymer pipelines, steel-polymer high pressure pipelines of small diameter for supply of chemical reagents to a well which provide accurate and reliable dosing of chemical reagents in required segment of well with minimal losses.

Specifications

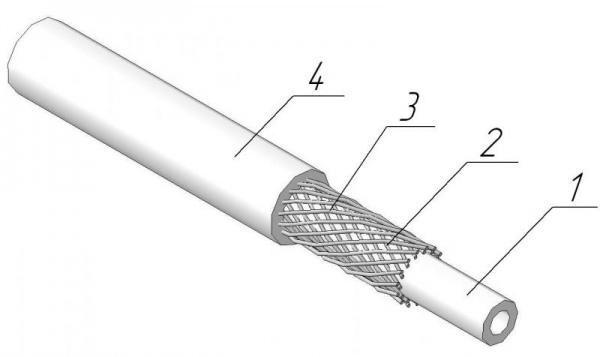

Capillary polymer high pressure pipelines

1 – polymerpipe

2 -1-wind of armour

3 -2-wind of armour

4 -sheath

Table 1 – Technical characteristics

|

Type |

Diameterin/out, mm |

Breaking force, kN |

Elongation, m/km/kN |

Minimal bending radius, mm |

Weight in air,

|

Weight in

water |

Maximal pressure, in/out, ÌPà |

Maximal operating temperature, °Ñ |

|

ÒG-5/15-150-25 |

5/15 |

25 |

0,7 |

300 |

270 |

135 |

15/20 |

90 |

|

ÒG-7/16-150-25 |

7/16 |

25 |

0,7 |

315 |

320 |

137 |

15/20 |

90 |

|

|

8/17 |

25 |

0,7 |

330 |

340 |

140 |

15/20 |

90 |

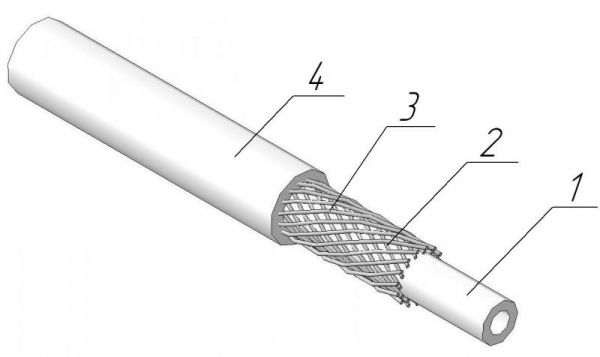

Capillary steel polymer high pressure pipelines

1 – steel non

corrosive tube

2 - 1-wind of armour

3 - 2-wind of armour

4 - sheath

Table 2 – Technical characteristics

|

Type |

Diameter, in/out, mm |

Breaking force, kN |

Elongation, m/km/kN |

Minimal bending radius, mm |

Weight in air, kg/km |

Weight in water kg/km |

Maximal pressure, in/out, ÌPà |

Maximal operating temperature, °Ñ |

|

|

4/10 |

25 |

0,7 |

300 |

125 |

60 |

50/20 |

90 |

|

|

4/12 |

25 |

0,7 |

320 |

185 |

86 |

50/20 |

90 |

|

ÒG-5/12-500-25 ÌÒ |

5/12 |

25 |

0,7 |

320 |

190 |

90 |

50/20 |

90 |

|

ÒG-6/15-500-25 ÌÒ |

5/15 |

25 |

0,7 |

350 |

270 |

125 |

50/20 |

90 |

|

ÒG-8/18-500-25 ÌÒ |

8/18 |

25 |

0,7 |

350 |

430 |

200 |

50/20 |

90 |

According requirements of a customer, pipes with other operating temperature can be produced.