Capillary systems

Description

Present oil production has complexities connected with the increased corrosion activity of output products, laying of not organic salts and asphalt-resin-paraffin deposits, formation of stable emulsions. Number of complicated wells is growing constantly by all production companies in all regions.

Engineering company “Inkomp-neft” formed over 10 years ago designs technical means and techniques directed to prevent complexities by oil production and eliminate its consequences. These are the systems of supply of chemical reagents into a well which provide an accurate and reliable dosing of chemical reagents to a required segment of well with minimal losses. New polymer load carrying pipelines of small diameter allow solving many technological problems in oil production.

Specifications

Now, oil production companies actively develop a strategy of intensification of production that leads to decrease of downhole pressure in perforation zone. This results shifting of an area where salts deposits begin to form near to the downhole of a well. While intensifying production, wide developed method of supplying an inhibitor to the area around production tube became not effective because the inhibitor is coming to the area where salt crystals already formed. The inhibitor is supplied through a dosing unit to the area around production tube, it comes to an inlet of the pump and moved away with fluid. In this process, a submersible electric motor, a cable and the column around production tube are not protected from deposits (Figure 1).

Figure 1 Supply of salt inhibitor to area around production

tube

Injection of inhibiting solution to the productive layer is limited by geological properties of the layer and is difficult to implement, and it leads to big outgo of the chemicals. In these conditions, supply of the chemical reagents through the capillary systems is the most prospective method with the capillary system being improved and adapted for use in different segments of a well.

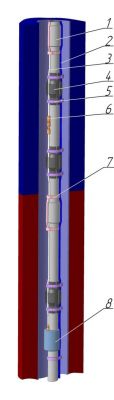

1. Supply of reagent to production tube (lay out ¹1) |

|

|

The dosing to the production tube is used to prevent the asphalt-resin-paraffin deposits. A chemical reagent moves through the well pipeline attached to the outer surface of the production tube and comes to the inlet muff (8), which has the centering unit for protection of terminations (6) and of a back valve. By this method of dosing, reagent reaches the desired segment before formation of deposits. Consumption of the expensive reagent can be decreased 2-4 times comparing traditional supply to the area around production tube.

1. Production tube;

2. Power cable for electric centrifugal pump;

3. Capillary well pipeline;

4. Centering unit;

5. Belt of cable attachment;

6. Connective element of well;

7. Protector;

8. Inlet muff with back valve.

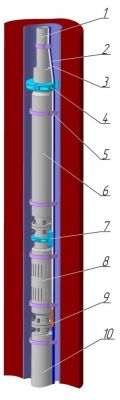

2. Supply of reagent to inlet of electric centrifugal pump (lay out ¹2)

Dosing of inhibitors of corrosion and salt formation to inlet of pump.

A chemical reagent is moving through the pipeline attached outside of the production tube to the valve-injector (9). A protector for a power cable (2) and for capillary pipeline (3) is set before this valve.By this dosing, the reagent comes to an inlet grid. Consumption of the expensive reagent can be greatly reduced comparing traditional way of supply to the area around production tube.

1. Production tube;

2. Well capillary pipeline;

3. Power cable for electric centrifugal pump;

4. Centering unit of pump;

5. Cable attachment belt;

6. Electric centrifugal pump;

7. Cable protector;

8. Inlet grid;

9. Valve-injector;

10. Submersible electric motor

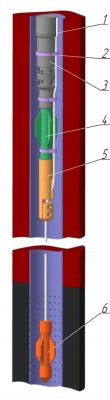

3. Supply of reagent to perforation zone (lay out ¹3)

Dosing to perforation zone to prevent salt deposits and corrosion.

A chemical reagent is moving through the capillary pipeline attached outside production tube and through the capillary pipeline’s attachment unit (5) along with the centering unit of an electric motor (4), to the load-injector (6).

By this way of dosing, the reagent reaches perforation zone before salt crystals begin to appear. With this method of supplying chemical reagent is excluded that electric centrifugal pump can be stuck as result of disrupting the plan-washers because the solid sediment deposits on the body of electric motor. Consumption of the expensive reagent can be significantly reduced comparing the traditional way of supply to the area outside production tube.

1. Well capillary

pipeline;

2. Cable

attachment’s belt;

3. Submersible electric motor;

4. Centering unit of motor;

5. Suspension;

6. Load-injector.