Mini-coiltubing equipment

Description

An idea to use the column of flexible steel pipes for underground repair of wells was developed first time in a middle of previous century but if a found broad use in Russia only on last 8-10 years.

Clear advantages using this technology are:

- Sealing of the wellhead at all stages of performance of downhole operations

beginning from preparation of set of repair equipment until its removal;

- Possibility to perform work in oil and gas wells without preliminary

killing them;

- There is no need in re-development of a well and stimulation of inflow

after work with a column of the flexibles.

- Safety of lowering – rising operations because there is no need to perform

screw and unscrew operations of threaded connections and put production tubes

to a scaffold.

- Significant improvement of working conditions for personnel by all

operations of underground repair;

- Decrease of time for lowering and rising of a downhole equipment to a project

depth;

- Providing possibility of drilling and lowering of drilling tools and

instruments;

- Conformance to high ecological requirements performing all operations of well repair and drilling because of smaller dimensions of set of equipment comparing with traditional.

However, work with the continuous column of steel pipes is complicated by necessity of providing of “comfortable” conditions for performance of steel pipe that leads to increase of diameters of reels, complimentary installations of big units as an injector, guiding etc. As result:

- Complex has a high primary cost;

- Drastic increase of dimensions of the ground equipment;

- Complicated complex leads to fairly frequent maintenance and repair;

- Decreased mobility;

- Necessary to increase the number of stuff and increasing demands on

qualification of stuff;

- High cost of the pipe with small resource leads to a very expensive single

repair;

Moreover, to ensure already small (around 100 lowering-rising operations) a warranty run without failure the additional equipment must be purchased:

- stands for winding pipe;

- test equipment for pipe;

- special welding equipment.

Thus, only companies with large production and technical base and qualified stuff can afford the traditional coil tubing.

All above indicated factors show that use of the coil tubing technology for small budget repairs became economically unjustified.

Specifications

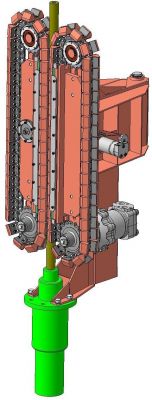

a)  b)

b)

Figure 1 – Mini coiltubing assembly: à) Coiltubing complex with flexible production tube. b) Mini-coiltubing complex with steel polymer pipe.

Use of the steel polymer pipe instead of a steel pipe on some operations of a well repair allows avoid some of above stated problems connected with properties of umbilical which are:

High flexibility and sufficient breaking force make possible to wind the umbilical on a reel with small diameter of core barrel or on a simple geophysical winch;

Using the pipe with electric conductors (umbilical), new technologies can be implemented combining hydraulic action with simultaneous control with electric signals;

Acceptable cost of installation and umbilical (cost of the ground equipment in a base form comparable with cost of a geophysical winch and cost of umbilical with cost of a geophysical armoured cable);

High corrosion resistance of the pipe allows supply of aggressive fluids (acids, alkalis).

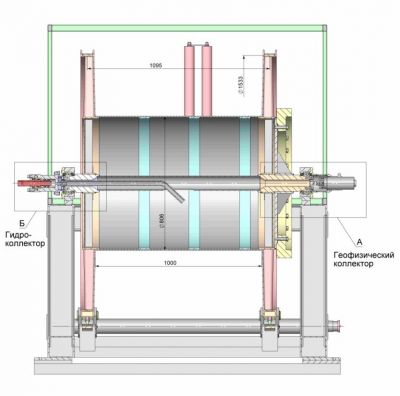

Figure 2. Mini-coiltubing assembly

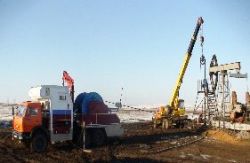

A complex for operations with the steel polymer pipe is shown on the Figure 2.

The complex contains:

- self-propelled

shassi based on the truck KAMAZ 4118 with all-wheel drive;

- winch with winded steel polymer pipe and cable by block for uniform winding

of the pipe;

- crane –manipulator;

- compartment with operator panel and resting places for working team;

- hydrocollector for supply of technological fluids to steel polymer pipe by

rotating reel;

- electric collector for receipt and transfer of electrical signal from lowered

to a well geophysical tool

- blow out

preventing equipment installed on a wellhead;

- injector for pushing of the pipe to a well with pressure at the wellhead

This set of supply combines reasonable costs and possibility to perform all range of works.